Rowenta Steamer Not Steaming! Fix Now

Your Rowenta steamer might not be steaming due to several issues such as a low water level, clogged steam nozzle, or a malfunctioning heating element. Ensuring the water tank is adequately filled and properly seated can often resolve this issue.

When facing a non-steaming Rowenta steamer, the first step is to check the water level in the tank. If it’s too low, the steamer won’t produce steam. Ensure the tank is filled to the appropriate level with clean water. If your model has a removable water tank, make sure it is firmly pressed down in place.

Sometimes, the problem might be a clogged steam nozzle, which can be caused by accumulated calcium or other debris. Regular cleaning and descaling of the steamer can prevent this issue.

In cases where the steamer makes a clicking noise but does not steam, it may indicate an electrical problem or a malfunctioning heating element.

For models like the Rowenta X-Cel or the commercial steamer, specific troubleshooting steps can vary. The Rowenta X-Cel, for instance, might face issues with its small transfer water line. This line can get blocked due to contamination from salts or debris, hindering steam production.

Why is Rowenta Steamer Not Steaming? How to Fix It?

Rowenta steamers are renowned for their efficiency, but like all appliances, they can encounter issues. Understanding these problems and their solutions ensures your steamer remains in good working condition.

1. Low Water Level

A common reason for a Rowenta steamer not producing steam is the low water level in the tank. Steamers need sufficient water to generate steam. If the water is below the required level, the steamer fails to operate properly.

To fix this, simply refill the water tank to the indicated level. It’s crucial to use distilled or de-mineralized water to minimize mineral buildup, which can also lead to operational issues.

2. Clogged Steam Nozzle

Over time, the steam nozzle can become clogged with mineral deposits, especially if tap water is used. This blockage prevents steam from being emitted. The solution involves cleaning the nozzle thoroughly.

Unplug the steamer and let it cool down. Then, use a small brush or a needle to gently remove any debris from the nozzle. For heavy mineral buildup, soak the nozzle in white vinegar for a few hours before rinsing it with water.

3. Faulty Heating Element

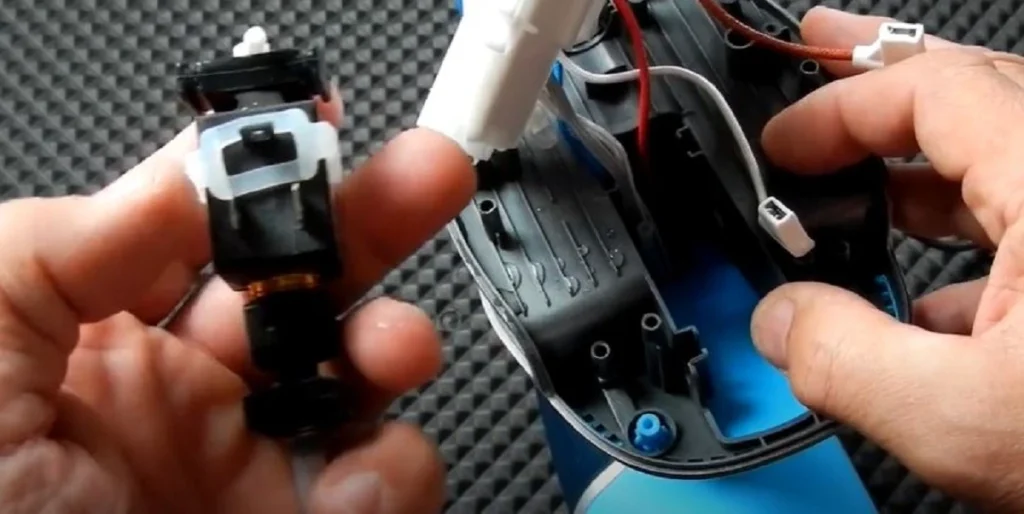

The heating element is crucial for converting water into steam. If this component is malfunctioning, the steamer will not produce steam. This can be due to electrical issues or wear and tear.

Fixing a faulty heating element typically requires professional repair or replacement. It’s advisable to contact Rowenta customer service or a qualified technician to handle this issue, as it involves the appliance’s electrical components.

4. Damaged Water Tank

A damaged or improperly sealed water tank can also be a culprit. If the tank has cracks or isn’t seated correctly, water might not reach the heating element efficiently. Examine the tank for any damage and ensure it’s correctly positioned in the steamer.

If the tank is cracked or broken, it will need to be replaced. Most Rowenta steamer models have replaceable tanks available through customer service or authorized dealers.

5. Electrical Problems

Issues with the steamer’s electrical system, such as a malfunctioning thermostat or wiring problems, can prevent it from heating up and producing steam. These problems often manifest as unusual noises or a complete failure to turn on.

Resolving electrical issues usually requires technical expertise. It’s best to avoid DIY fixes for these problems, as they can be hazardous. Instead, seek assistance from a professional technician who can diagnose and repair the electrical system safely.

Inside the Mechanics of a Rowenta Steamer

Rowenta steamers operate on a simple yet effective principle. Water from the tank is heated by an electric heating element, turning it into steam.

This steam is then directed through nozzles or a steam head, which is used to smooth out wrinkles on fabrics. The steamer has a thermostat that regulates the temperature to ensure consistent steam production.

Some models come with features like adjustable steam settings or a steam trigger for more control. A safety feature in most Rowenta steamers is an automatic shut-off system that activates when the steamer runs out of water or is left unattended for a certain period, ensuring safety and energy efficiency.

Read More: Is Conair Steamer Not Working? Here’s the Solution

Rowenta Steamer Making Clicking Noise

A clicking noise in a Rowenta steamer usually signifies an issue with the water heating mechanism. This sound often occurs when the steamer is trying to heat the water in the tank, but is unable to produce steam. The causes can range from a low water level or a malfunctioning heating element to a clogged steam nozzle.

To troubleshoot, first, ensure the water tank is adequately filled. If the problem persists, inspect the steam nozzle for any blockages and clear them.

In cases where the heating element is suspected to be the issue, professional assistance may be required as it involves the appliance’s internal electrical components.

Comparing Rowenta Steamer Models: Issues & Solutions

Rowenta X-Cel

Difficulty in generating consistent steam, nozzle clogs. Regular cleaning, descaling, ensuring proper water level

Rowenta Commercial Steamer

Challenges with continuous steam flow, and durability in heavy usage. Frequent descaling, checking for wear and tear, proper storage

Rowenta Pro Compact

Problems with steam generation, and water tank issues. Regular maintenance, checking electrical connections, using distilled water

Rowenta 1550w Steamer

Inconsistent steam temperature, and mineral buildup. Regular descaling, using filtered water, timely cleaning of the steam head

Rowenta Handheld Steamer

Portability affecting water tank stability, and quick mineral buildup due to frequent use. Regular checking of water tank alignment, frequent descaling, proper storage after use

Preserving Your Rowenta Steamer

The longevity of a Rowenta steamer heavily relies on effective maintenance practices. Regular cleaning is crucial to prevent mineral buildup, especially in areas with hard water. Descaling is necessary to remove calcium deposits that can clog the steaming mechanism.

Using distilled or de-mineralized water instead of tap water can greatly reduce the rate of mineral buildup. Adhering to a maintenance schedule, which involves cleaning and descaling at regular intervals, is key to ensuring the steamer operates at its best.

Proper storage of the steamer is important. This includes emptying the water tank after use, storing the steamer in a dry place, and avoiding exposure to extreme temperatures or humidity, which can damage the internal components and outer casing of the steamer.

Learn More:

Discover New Articles: See Our Latest Updates